The path to your optimum DC-Link solution.

We provide professional and extended advice on the selection of the most suitable capacitor for your application, taking into account the electrical performance, the available installation space, the fastest possible availability in urgent cases and, of course, the costs.

To do this, we analyse your load profile and consider

The core temperature increase

The effect of voltage and current peaks on the service life

The expected number of cycles for repetitive charge-discharge applications

The expected lifetime at your specific load or under different configurations

The possible optimisations through cooling to enable exceptional current-carrying capacities.

Saving costs and installation space

In order to avoid unnecessary oversizing and cost increases for your DC-Link bank and notwithstanding loads that are often beyond the official specifications, we check very carefully which overloads are still acceptable and above which point a different capacitor is required in order to achieve the required lifetime.

Take advantage of our free service

We offer

Solutions to design with more compact and less expensive capacitors

The product with the best price-performance ratio

Sample with integrated thermal sensor within a few weeks

Recommendations for the symmetry of series connections

Solutions for correct mounting under high external mechanical loads

The joint evaluation of your operational test results

Lifetime calculation tool

Perform your own simulation of your specific temperature and load profiles in our LIFETIME calculation tool to find out the effect on the expected service life and thus make your own preselection of products.

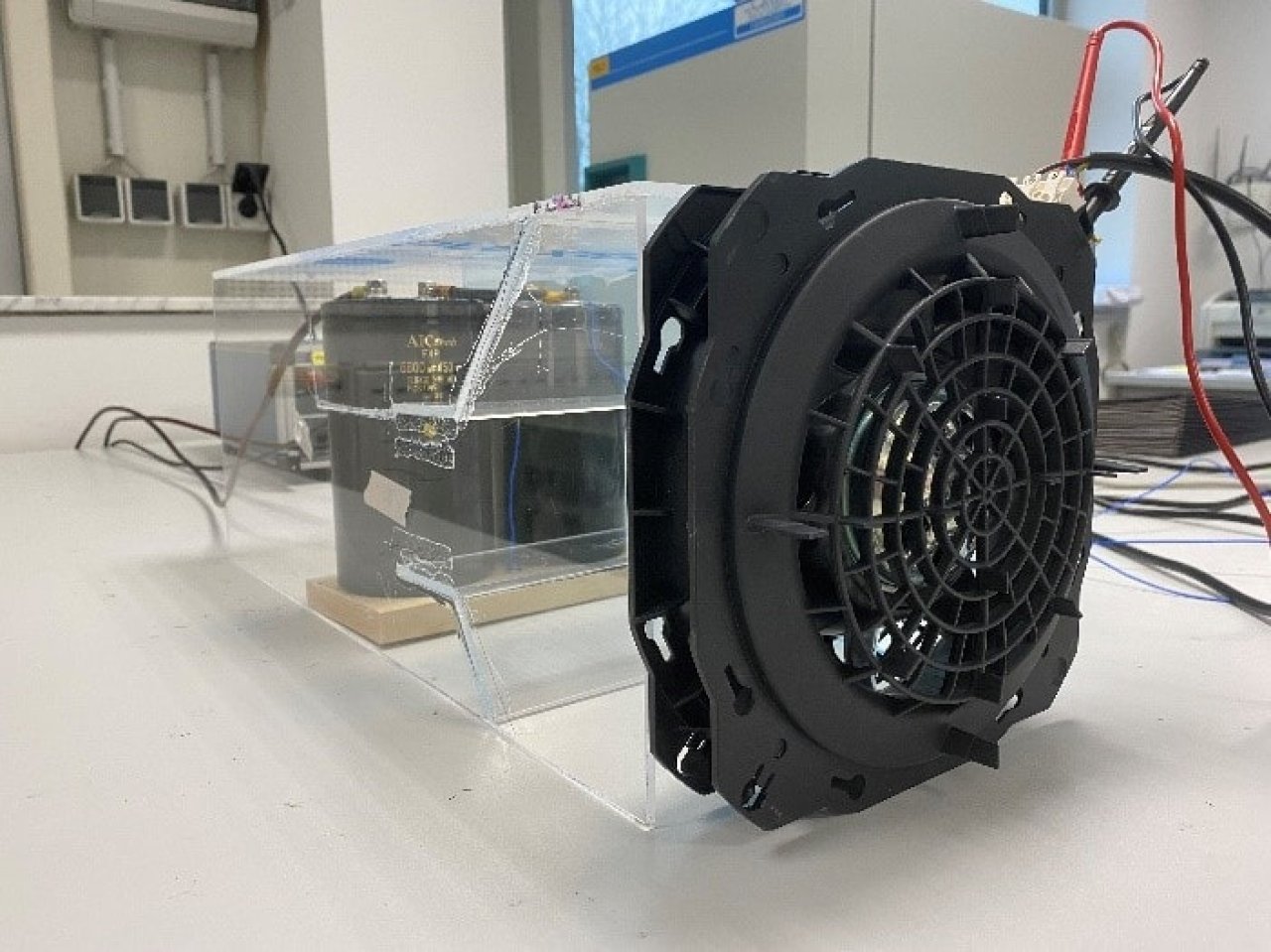

Laboratory and testing facilities.

In addition to leakage current measurements, the typical tests include

ESR vs. frequency vs. temperature

Load and overload tests

Testing of customised or abnormal load conditions

Accelerated lifetime tests

Investigation of field returns - estimates of remaining service life

Installation of thermocouples for stock items and samples

Tests with active cooling

Comparison test with competitor products

Investigation of damaged capacitors - request root cause analysis & support!

In cooperation with the manufacturer, we also examine defective capacitors and strive to identify the possible root cause of the failure. In particular, the basic materials are checked for their properties and specifications in order to rule out serial defects.

Just ask for our support.